How to find problems lurking behind the scenes

Surface temperature can tell you a lot about a building’s structural elements, plumbing installations, HVAC and electrical systems. Problems that are otherwise invisible to the naked eye are suddenly clear as day when you look through an infrared lens. Air leakage, moisture accumulation, blockages in pipes, structural features behind walls and overheating electrical circuits can all be detected and visibly documented with a handheld thermal imaging camera. By scanning surfaces with such an inspection tool, you can quickly locate temperature variations, which are often indications of underlying problems, and document them with detailed images in reports. By pinpointing potential sources of problems, you also save valuable inspection time and repair only what needs to be fixed, rather than performing repairs regardless of actual need. Repeated temperature measurements of the same targets can determine whether repairs were successful and help anticipate future repairs

Looking behind the scenes

Thermal imaging cameras are a handheld infrared temperature measurement tool. These devices immediately show you the hot and cold spots in the form of thermal images. My Fluke thermal imager camera includes IR-Fusion, a technology that fuses a visual image with an infrared image (colour image within a black & white image) for better identification and analysis. The dual images are accurately aligned at any distance heightening details, making it much easier to spot where further investigation is needed. Thermal scans can identify and establish the extent of thermal anomalies within new or existing buildings, for example

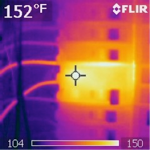

Inspecting electrical systems:

Safely locate overheating components in electrical systems, expressed as hot spots in thermal images.

|

|

| hot circuit breaker | hot spot on furnace |

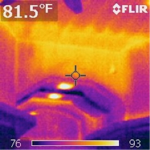

Checking for missing and damaged insulation:

Inspections both inside and outside structures show you the location, shape and intensity of insulation.

|

|

| missing insulation in wall | missing insulation wall chase |

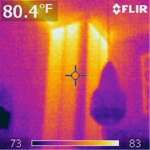

Pinpointing air leakage points:

Reducing air leakage, or the uncontrolled movement of air into and out of a building is also important because it can compromise the efficiency of building environmental systems. While best measured with pressurization testing, infrared scans can quickly pinpoint leakage points. Inspections inside and outside of structures, along doors, windows, vents and pipes, immediately show you areas of infiltration and exfiltration.

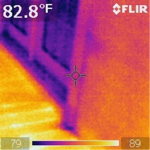

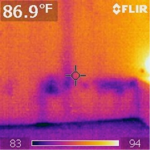

|

|

| air leakage in duct work | air leakage around door |

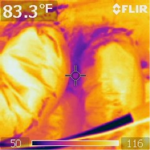

Finding areas of moisture accumulation:

Moisture intrudes through joints and cracks in roofs, ceilings and walls, and is trapped, resulting in structural rot and mold, some of which may represent serious health hazards. Regular infrared inspections, inside and outside of structures, are therefore critical to quickly locate cold spots, which are often signs of moisture intrusion.

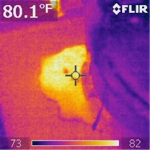

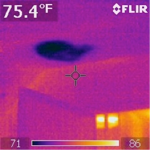

|

|

|

| leaking pipes in wall | leaking around toilet | moisture in ceiling |

Verifying structural elements:

Infrared camera inspections can help you quickly locate support beams, pipes, electrical cables, and flues in poured walls, floors and ceilings. Simply scan surfaces, and detailed thermal images clearly show you subsurface details.

In summary, there are a number of reasons why you should add an Infrared (thermo) Camera Scan inspection to your Home Inspection. Most importantly, infrared scans can save you a lot of time and effort in locating existing and potential problems, which can jeopardize not only building performance, but also with the buildings health and safety issues.